Critical machine parts like separators, cooling towers, blowers, generators, pumps, bearings and motors usually give hints they are damaged and about to fail. When a fan becomes unbalanced or bearings start failing, they start vibrating more. Although this change wouldn't be noticeable to the human eye or ear, it's easily detected by a vibration sensor.

A remote monitoring system like the Sensaphone Sentinel uses sensors that monitor for excessive vibration. They detect damage early, so you can take preventive action and prevent a total failure.

The advantages of this predictive maintenance are well-documented. Detecting a problem or flaw immediately can save you significant time and money from equipment damage and downtime. They can also alert you when a machine has stopped entirely because it notices that the part's vibration drops below a certain value.

How do vibration sensors work?

Magnetically mounted to an air compressor motor, the sensor logs how long the compressor is running and will also alarm if the vibration becomes too intense.

Every rotating machine has its own vibration characteristics. When a part starts failing, those characteristics change. For example, when a rolling element bearing is damaged, it becomes unbalanced. It starts vibrating at a different frequency, leaving a dynamic fingerprint.

A vibration sensor measures the vibration velocity (e.g. severity of vibration) of a machine from 0-25 mm/s (rms) over the frequency range 10-1000Hz. An output of 4mA will correspond to 0 mm/sec (e.g. no vibration), and an output of 20mA corresponds to 25 mm/sec (intense vibration).

Sensors are installed in three easy steps:

- Permanently attach the sensors to the machine by a magnetic mount or screw them in via the sensor’s threaded mount

- Hard-wire sensors to a remote monitoring system

- Program your system to alarm and data log the information coming from the sensor

The sensor communicates its frequency readings in real time to the remote monitoring system. You set the system to "alarm" when an out-of-limit value is detected. This gives you time to take action to prevent catastrophic failure, secondary damage, and expensive downtime.

Diagram was produced by ifm US, a leading provider of industrial automation products

Looking for trends

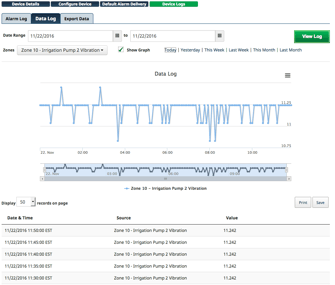

This screen shot shows a real-time view of a vibration sensor through the Sensaphone Sentinel web interface.

Vibration sensors integrated into a remote monitoring system make an ideal data logger. The sensors capture readings at set time intervals. You can view these readings in real time and analyze for trends that indicate an imminent failure.

Parts ideal for vibration monitoring:- Separators

- Rolling stand bearings

- Motors driving hydraulic pumps

Vibration sensors serve as an early indicator of product damage or failure. By sending an alert as soon as they detect abnormal activity, they help you solve problems before they turn into serious issues.

To learn more about vibration sensors and our broad range of early detection products, contact one of our experts today.