An RTD temperature sensor otherwise known as a resistive temperature detector probe often provides the most reliable temperature measurement when remotely monitoring extreme-temperature environments. Read on to learn more.

Many industries rely on remote monitoring systems to track and control the temperatures of a facility, process or environment that can affect equipment operation, staff performance and productivity. For example, a control room that is too hot can be detrimental to equipment performance while a too-cold greenhouse can negatively affect product output.

A variety of temperature sensors are on the market that interface with remote monitoring systems such as the Sensaphone Sentinel monitoring system. Choosing one depends on the requirements of the application and environment. Certain applications require technology such as RTD sensors with the capability to measure extreme temperatures.

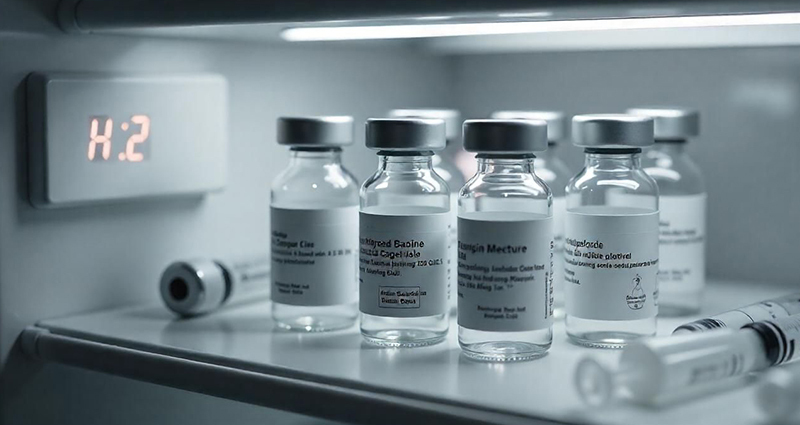

For example, maintaining a stable ultralow temperature in liquid nitrogen tanks is vital to the cryopreservation of sensitive cells, tissues and other sensitive biological materials. If air temperatures rise higher than the -140 °C maintained in liquid nitrogen, the tank is not cold enough to preserve critical biological material.

To ensure the safe storage of these irreplaceable samples, in vitro fertility clinics, research laboratories and other medical facilities require a remote monitoring system with a temperature sensor that can tolerate extreme temperatures to properly report conditions and trigger alarms when they fall outside of set limits.

RTD Sensor Extends Temperature Measurement

While some standard temperature sensors can operate in extended temperatures from -109°F to 115°F, the RTD sensor monitors air temperature from -326 °F to 248 °F (-200 °C to 120 °C). Used exclusively with Sensaphone’s web-based WSG 30 monitoring system, the RTD probe measures air temperatures in applications where standard sensors fail.The RTD temperature sensor wirelessly communicates with the WSG30 system via an integrated 2.4 GHz wireless radio to provide input on temperature parameters. Multiple sensors can create a mesh network, which allows each sensor to be used as either a wireless sensor/router or as a low-power, battery-operated sensor.

The Sensaphone monitoring system stores data collected from the temperature sensor in the cloud. Users can get real-time status updates anytime, anywhere from the convenience of their phones and set alarms for notifications when temperatures pass limits.

A one- or 14-inch RTD probe is configurable with the sensors. In the liquid nitrogen tank application, a one-inch probe would be installed just below or inside the tank’s cap so that the sensor cabling is not exposed to the cold atmosphere. The wireless sensor can be placed up to 300 feet away from the WSG30 unit or farther if multiple sensors are used to create a mesh network.

Benefits of RTD Sensors

RTD sensors offer many operating advantages over other temperature-sensing technology including:

• Wide temperature ranges of -326 °F to 248 °F (-200 °C to 120 °C).

• Excellent accuracy, usually within + -0.5 °C of actual temperature.

• Stable output with sensor voltage almost constant between readings.

• Response time of less than one second.

While RTDs are available in different metals for its temperature-sensing elements, Sensaphone’s WSG RTD wireless temperature sensor uses a 100 ohm platinum RTD probe. The platinum offers excellent long-term stability, corrosion resistance and higher melting point.

High-Temperature Monitoring Applications

Sensaphone’s wireless RTD sensors are ideal for use in a variety of remote monitoring applications that require monitoring high and low temperature ranges with high accuracy including:

• Facility operations such as hydraulic systems, industrial ovens and tank heating systems.

• Power generation equipment including turbines and generators.

• Process control operations in pharmaceuticals, which are especially prone to temperature fluctuations.

• Chemical industry processes where reactions must be controlled.

• Refrigerators and freezers in food manufacturing facilities with ultracold storage requirements as low as -80C.

• The internal temperature of a substance in a tank.

Sensaphone can configure or update a wireless remote monitoring system to measure extreme air temperatures in applications where traditional sensors prove unreliable.

Find out more about our WSG Wireless RTD Temperature Sensors or contact our sales team to guide you in the selection of the right sensors and monitoring system to address your current and growing needs.