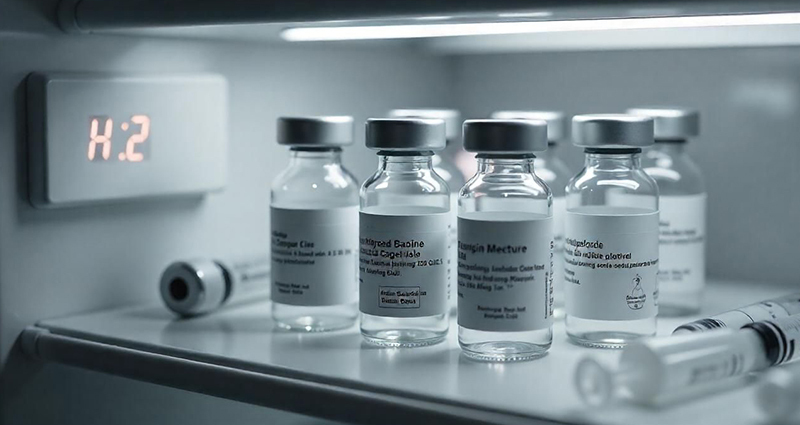

Temperature monitoring is essential in the medical industry, which stores valuable vaccines, pharmaceuticals, and research samples costing hundreds to thousands of dollars in refrigerators or freezers. Products maintained at inappropriate temperatures can deteriorate their potency, potentially causing serious issues such as rendering medications ineffective. NIST temperature sensors connected to remote monitoring systems provide the capability to track temperature changes in refrigerators and freezers to ensure product integrity.

Importance of Temperature Control

Every drug has its specific storage requirements. Some require refrigeration, some must be stored below freezing, while others may lose potency if frozen. For instance, insulin typically needs to be stored at temperatures between 2°C and 8°C (36°F and 46°F) for optimal efficacy. One of the best ways to ensure medical refrigerators are working effectively at the right temperatures is using NIST temperature sensors with a remote monitoring system.

In its Vaccine Storage and Handling Toolkit, the CDC underlines the necessity of continually monitoring vaccine temperatures and taking immediate corrective action if temperatures deviate from the recommended range. If a facility cannot prove with certainty that vaccines were kept within the required range, the CDC advises their disposal, which can result in losing millions of dollars in inventory or years of research.

According to the World Health Organization, about 50% of global vaccines may be wasted annually because of temperature control, logistics, and shipment-related issues. Vaccine recalls due to inappropriate temperature storage can result in:

- Extra doses for patients

- Damage to public confidence in vaccines

- Increased costs for providers

- Liability for a provider's practice.

Remote Temperature Monitoring

A remote monitoring system configured with NIST temperature sensors allows personnel to continuously check on temperatures of critical vaccines, samples, and products at any time, from anywhere. In addition, the system is configurable to send instant alarm alerts if temperatures vary from set parameters. Data logging and storage capabilities also support secure record-keeping.

A documented system is necessary to ensure compliance with CDC safe practices and handling procedures. This includes continuous data logging, alarm logs, audit trails, and reports.

A remote temperature monitoring system can ensure your medical refrigerators are working effectively and in compliance to avoid fines, penalties, or even directives from inspectors to dispose of valuable products.

Going Wireless

For locations where wiring poses a challenge, a wireless monitoring system offers an easy and adaptable solution as it removes requirements to physically connect sensors to the base unit.

Wireless NIST temperature sensors are critical components when using these systems in medical refrigerator monitoring applications. They can be placed up to 300 feet away from the base unit or further if using multiple sensors to create a mesh network. They measure temperatures from -58° to 176° F (-50° to 80° C).

Paired with a bottle filled with glass beads or glycol, these temperature sensors provide readings that reflect the actual temperature of the contents within the fridge or freezer, instead of the ambient air temperature. The liquid inside the bottle serves to buffer sudden temperature changes caused by defrosting, a door opening, or air circulation by fans.

That means you get accurate temperature readings of stored products—not the surrounding air. Bottled wireless temperature sensors also stop the system from sending unnecessary alarms. The glass beads or glycol slow the sensor's response time, preventing routine operations from setting off an alarm.

It's worth mentioning that glycol-filled wireless temperature sensors adhere to the CDC's recommendations for monitoring vaccine storage in medical fridges. These sensors are often preferred by regulatory bodies over those filled with glass beads. We recommend the WSG wireless temperature sensor used with the VFC Refrigerator Temperature Sensor with Display for CDC applications. These sensors are used exclusively with the Sensaphone WSG30 monitoring system.

Consider Probes for Cold Storage

When monitoring environments with extremely cold temperatures, a temperature probe may be a better option than a sensor as it is more resistant to harsh conditions. Sometimes, a probe is configured with a temperature sensor.

A temperature probe can withstand temperatures too cold for most sensors or contact-type switches. Because they are so hardy, a temperature probe can be placed in a cold and wet environment that could ruin electronics or be inappropriate for a thermometer. The probes also can use a buffer (as previously described) to avoid from reacting too fast and triggering a false alarm.

Sensaphone's line of probes feature 12' wires that plug directly into a monitoring system. However, there is an option to essentially create a wireless temperature probe system.

By plugging a temperature probe into a wireless NIST temperature sensor, like the WSG Wireless Ultra Low-Temperature Sensor, you can send temperature readings from the probe to the wireless temperature sensor. The wireless sensor sends all data back to the remote monitoring system. This configuration creates a wireless temperature probe.

The monitoring system can receive inputs from up to 29 other wireless NIST temperature sensors. Each sensor can connect with a temperature probe. This wireless temperature probe allows greater flexibility in the placement of the probe, sensor, and remote monitoring system. You can log in to the base station to program and view current temperatures from one location.

NIST Certification Ensures Accuracy

How can you be sure that your sensors or probes are indicating the correct temperature? A NIST traceable certificate provides that assurance. This certificate indicates how close the temperature probe reading is to the internationally-recognized standard maintained by the National Institute of Standards and Technology (NIST). All equipment used to produce NIST traceable certificates is also NIST traceable, with measurements trackable to a single reference.

Sensaphone provides NIST temperature sensors that carry Traceable Calibration Certificates. Each certificate states the serial number, calibration date, and calibration data. Calibration is performed within the month of the sensor purchase.

These certificates validate that the sensors are calibrated according to the standards set by the National Institute of Standards and Technology (NIST), a U.S. Commerce Department agency. This assures that manufacturers and laboratories are adequately equipped to calibrate equipment to NIST standards and that their products align with NIST-regulated measurement standards.

A Sensaphone temperature sensor with NIST calibration consists of three temperature points: 15 °C, 0 °C, and 25 °C. If wanting to calibrate the probe at a certain temperature point, you can specify up to four temperature points per calibration. You can use a custom calibration of any temperature between -30 °C (-22 °F) to 55 °C (131°F).

Sensaphone also offers recalibration services for temperature sensors and probes. Annual recalibration ensures more accurate temperature readings and the quality of products stored in refrigerators. We can perform this server while eliminating the risk of downtime.

If you have specific questions about which NIST temperature sensor is right for your refrigerators and freezers, we are happy to make a recommendation. We have a variety of sensors and remote monitoring systems for medical cold storage applications. Systems are available with hardwired or wireless sensors, depending on your needs. Let us help you find the perfect solution for your facility. Contact us today.