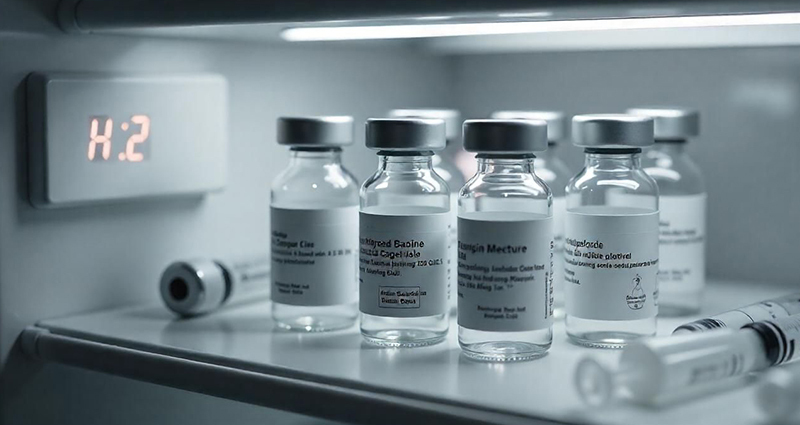

The Sensaphone WEB600 system monitors environmental conditions in smaller locations such as server rooms, vacation homes, office buildings and medical storage facilities that are not occupied around the clock.Most often our products are installed by trained installers or electricians, but they are actually simple enough to be installed by most do-it-yourselfers. The WEB600 system has a straightforward setup for the central communications device and sensors. This new video playlist addresses every step of installation and programming.